VBM 200F for Monitored Dosing

Efficient, safe and reliable multi-dose blister packaging

The VBM 200F streamlines the preparation of multidose blister cards with intuitive software, advanced vision technology, and complete traceability. By automating manual tasks, it saves time, reduces errors, and frees up staff to focus on patient care.

Brochure VBM 200F for Monitored Dosing download

Advantages

- Cost-effective automated solution for multiple dosing

- Significant time savings

- Scaling options: the VBM supports both single and multiple machine workflows

- Minimal risk of errors

- Integration with hospital and pharmacy software

- Easy to maintain

Set-up

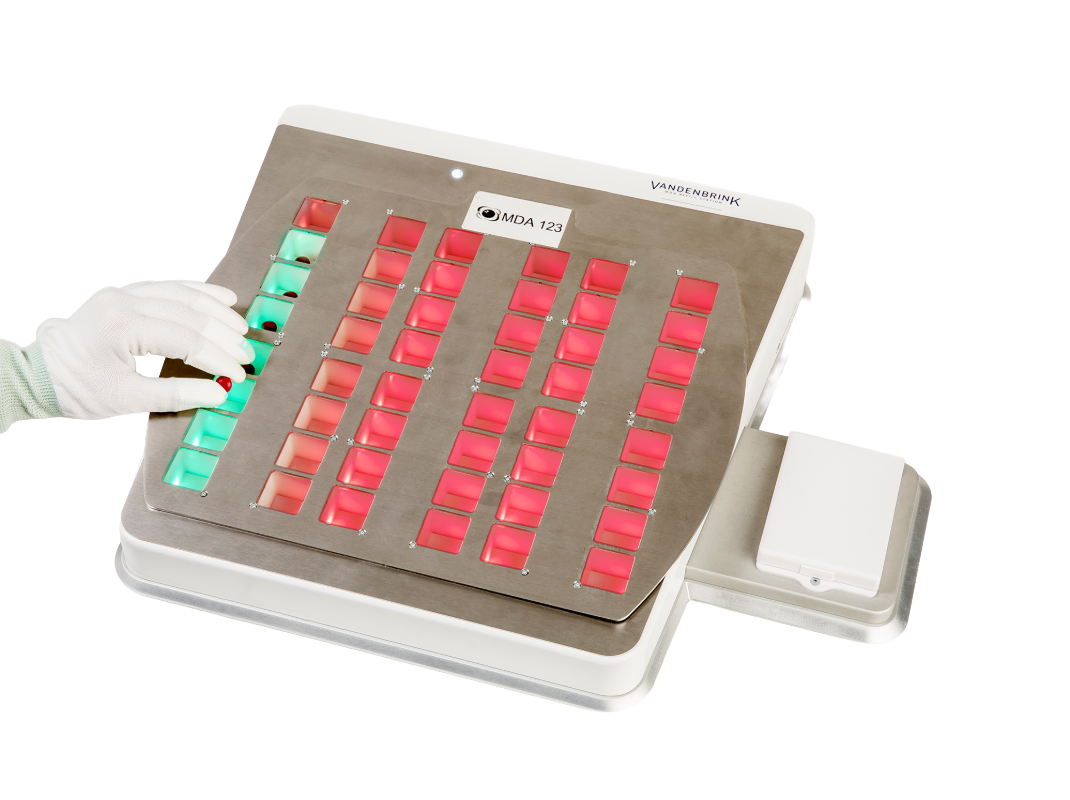

The VBM workflow begins with the creation of a pill library in the Vision Station. The VBM then automatically dispenses and verifies the correct medication per cup. Special medication is added via the MDA or Prefill Station. The blister cards are then checked, corrected and labelled in the BCO Station to create a completely accurate, patient-specific card.

Technical specifications

Amount of cartridges

200

Dimensions

Width (mm): 1965

Height (mm): 2061

Depth (mm): 823

Weight

635 kg

Power consumption

800W

Operating environment

5-40°C and <80% RH non-condensing

Maximum card size

265x220x25

Pill size lenght/width limitation (mm)

5 - 23

Pill size thickness limitation (mm)

1.5 - 8.5

Maximum throughput

30-40 cards/hour

(blister format 4x7)

Brochure VBM 200F for Monitored Dosing download

Options

Similar products

Interested?

All of our products are top-of-the-line, but which solution is best suited to your needs? Compare our models and discover which product will make a difference in your business.